EMG Strip Guiding System

Quality during continuous strip processing

For metal strip production, treatment and processing, the material, which is supplied in the form of coils, is unwound and then fed to the production process. In most cases, it is rewound into coils thereafter so as to allow convenient transport. Due to its geometric shape, metal strip tends to run unevenly on the deflector rolls in the production line.

The strip control system serves to keep a strip, which shows such tendency, in the centre of the equipment or in any other defined position. Thereby the strip control prevents damage to the product or the production equipment and ensures that the strip runs evenly through the production process.

Due to ever increasing quality requirements and high availability in combination with reduced operating and maintenance staff, however, requirements are constantly increasing which has a great impact on the quality of strip control systems and their components.

Application

Strip Guidance on The Uncoiler

Prop. Steering Guide

Strip Guidance on The Coiler

Prop. Integral Steering Guide SRH

Three Roller Steering Stand SRHT

Steering Frame SR

Steering Stand for Chemical Processing SRHQ

Strip Guidance System in a Continous Furnace

Strip Centering on Welding Machine and Stitches

Products

STRIP EDGE and CENTER POSITIONING DEVICE EVK/EVM

The EVK edge sensor positioning device and the EVM centre sensor positioning device are used for the non-contact strip edge and strip centre sensing of steel strip.

INDUCTIVE STRIP EDGE POSITIONING SENSING VKI3

In the harsh environment of a rolling mill where there is a high presence of rolling oil, atmospheric pollution and dirt, optical sensors that are used for monitoring the edge position of the strip require intensive maintenance and even then do not fulfil today's requirements in terms of operational reliability and availability. EMG's VKI3 sensor uses an inductive measuring principle with a coil system, which is designed to reliably detect the precise position of the edge of metal strip and foil material in this environment in a contact-free manner.

.png)

HYDRAULIC CONTROL SYSTEM HST

A HST hydraulic control system is used wherever installation space is at a minimum. It can even be used in close proximity to the hydraulic cylinder. The HST system is supplied by the central hydraulic system or a hydraulic power pack (HA)

EMG SPC DIGITAL CONTROLLER

Function is for Strip Position Controller. Suitable for all EMG strip guidance systems.

The large number of assignment possibilities allows various control alternatives.

The control functions are programmed and documented using the EMG-CAD system. The program is downloaded to the CPU using a PC, where it is saved in zero-stable mode.

EMG ICON IO EXTENSION MODULE

By expanding the control system with the EMG iCON® IO extension module, the system is able to provide a variable performance:

- EMG iCON® IO - Input Output

- Compact mechanical design

- Housing can be accommodated directly on a DIN rail

- Fixed firmware, non-configurable

- CANopen bus interface between the modules

- Spring-loaded terminal, connection max.1.5 mm²

- Integrated 10/10 digital inputs/outputs

- Integrated analogue AD/DA interface

- Integrated final amplifier for servo valves

LINE SCAN CAMERA CCD PRO

The CCD Pro line scan camera provides exact detection of strip edges and the strip centre position.

FURNACE SENSOR EMG VIVALDI

Innovative Strip Centre Measurement in High Temperature Ranges

The EMG-Vivaldi® sensor is located outside the furnace and conducts its measurements through the gas-tight furnace wall flange. The sensor system, which is mounted externally on the furnace wall, focuses electromagnetic waves through the non-conductive insulation of the furnace and onto the edge of thin metal strip material. As a result, cooling systems are no longer required for the sensors. As the furnace wall is completely enclosed, the strip is not able to damage the sensor itself.

.png)

SERVO VALVE TYPE SV1-10 & SV2-16

Servo valves are Hydraulic component for industrial applications and the most important components in any electrohydraulic control system. EMG rotary valve design with gap height control ensures minimum friction loss, high repetition accuracy and a large power range for single-stage valves

EMG ICON INTELLIGENT CONTROL SYSTEM

All applications for strip guiding systems and quality assurance systems

Roll stand or furnace control in conjunction with EMG iCON® IO

Applications involving moving large masses (e.g. recoiler and uncoiler) in conjunction with EMG iCON® SV

Use of long position measuring systems (e.g. double head coiler) in conjunction with EMG iCON® IS

EMG ICON IS EXTENSION MODULE

The EMG iCON® IS Intelligent CONtroller is an extension module for the EMG iCON® strip position controller.

The EMG iCON® IS can evaluate incremental sensors and/or SSI sensors on two channels

and transfer the results to the EMG iCON® via the EMG sensor/actuator bus (CANopen).

INDUCTIVE STRIP MEASUREMENT SMI

The measuring principle of the SMI sensor family (Strip Measurement Inductive) is based on electromagnetic induction. Two centre sensors are arranged at the strip edges at right angles to the strip pass line level and symmetrically to the system centre, and they are configured in such a way that the strip passes between the sensors as centrally as possible. The centre sensor that is located above the strip functions as a transmitter and the opposite sensor functions as a receiver.

HYDRAULIC CONTROLLER HR/HA

The HR hydraulic controller and the HA hydraulic power pack generate reliable hydraulic energy for any power range. A HR hydraulic controller is a HA hydraulic power pack with a servo valve, which regulates the volume flow of the fluid.

Standard hydraulic units fundamentally consist of an oil tank, a motor/pump assembly and a filter. Pressure-regulated pumps with variable displacement are used. If cooling is required, either air or water cooling units may be used.

.png)

ELECTRO SERVO CYLINDER ESZ

Electromechanical drive for the harshest environmental conditions.

Based on a simple functional principle, the ESZ electric servo cylinder ensures maximum positioning accuracy even when subjected to the harshest environmental conditions. The preferred place of installation is in the furnace area, as flammable hydraulic oils are undesirable in the hot area. Utilisation on a carriage system, where the installation of hydraulics is often difficult or even impossible, is not a problem.

The ESZ represents an alternative to hydraulically operated variable speed drives.

EMG ICON VS VISUALISATION SYSTEM

High degree of user-friendliness thanks to the intuitive user interface with touch functionality

Languages can be changed online

Alarm management / alarm list included

Plastic housing for installation in a control cabinet door (optional: lockable protective cover)

For furnace control installation in a control cabinet

EMG ICON SV EXTENSION MODULE

The EMG iCON® SV Intelligent CONtroller is used as a final amplifier module with a secondary control circuit for two-stage servo valves.

Equipped with the EMG sensor/actuator interface (CANopen), an analogue input for the stroke transducer of two-stage EMG servo valves and a final amplifier.

The EMG iCON® SV can be used to control the two-stage EMG servo valves SV 2-16, SV 2-50 and SV 2-10

EMG Quality Assurance System

EMG IMPOCPro

Online Measurement of Tensile Strength and Yield Point

EMG IMPOC is a tried and tested, magnetic-inductive measuring system for automatic, non-destructive online determination of the mechanical properties (tensile strength and yield point) of ferromagnetic steel strip material.

Areas of application include the production of cold-rolled and surface-coated steel strip material, for example, in:

-

Hot-dip Galvanizing Lines

-

Continuous Annealing Lines

-

Tinning Lines

-

Continuous Pickling Lines*

-

Processing Lines*

*on request

EMG SORM 3 PLUS

Online Roughness Measurement

Consistent measurement of surface parameters that are of significance for the production process.

SORM 3plus is an online measuring system that is used for detecting roughness parameters on running strip material. The roughness parameters are an important quality feature of uncoated and surface-refined strip material. The standardized method of measurement that has been used to-date involves using a stylus instrument. When using this method the operator needs to stop the production line or take samples from the coil, after which, measurements are conducted offline in a lab.

In contrast, SORM 3plus is a contact-free, online measuring system that can be used for metallic and many non-metallic surfaces at production speeds of up to 2400 m/min.

EMG eMASS

Electro Magnetic Strip Stabilization Stable strip in coating processes

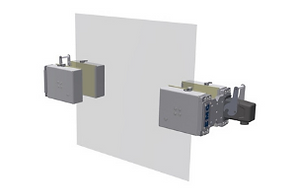

EMG eMASS® is a turnkey system for stabilizing high-speed ferromagnetic steel strip material based on electro magnets. The main area of application is to optimize and economize the use of the metal coating at the blow-off nozzle of a hot-dip galvanizing line for zinc coating, GALVALUME®* and aluminisation processes.

The system is installed above the air knife and as close as possible to the air knife lip, which wipes off the liquid metallic layer. Based on the experience of more than 50 installations around the world, EMG designs the integration of eMASS® systems for the air knife area in an optimal and customer-specific manner.

EMG eBACS

Baffle Blade Control System

In hot-dip galvanizing lines the zinc coating thickness on the metal strip is determined by means of compressed air-driven blow-off nozzles (air knives) that are located immediately above the zinc pot. The metal strip passing through the system is enlarged by so called "baffle blades" in this area. The aim of using these baffle blades is to avoid any form of air turbulence, which can lead to damage of the zinc layer in the area around the strip edge.

In this application the baffle blades must continuously follow the strip edges, whose position can change due to swarming of the strip or alteration of the strip width. Inductive edge sensors here enable high-precision and contact-free tracking of the baffle blades, thereby preventing damage to the strip edges that can otherwise be caused by the chipping of zinc and/or through the mechanical contact of rollers.

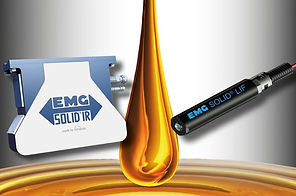

EMG SOLID

Online Oil Layer Measurement

EMG SOLID® is a system that is used for the online measurement of oil layers on running strip material within the production line to determine the layer over the entire width and length and then visualizes it over the entire measured surface.

(SOLID = Surface Oil Layer Inline Determination).

EMG HotCAM

Optical Position Measurement on Hot Strip

The hot rolling process is typically a combination of a reversing stand (roughing stand) and a finishing line with several roll stands.

To ensure process reliability in a hot rolling mill, it is extremely important to maintain a defined position of the strip between the roll stands. The continuous measurement of the strip position enables an optimum adjustment of the rolling force and rolling gap.

In reversing stands this leads to a reduction of the camber of the strip and thus prevents collisions of the strip with the mechanical strip guiding rail.

EMG BREIMO

Strip Width Measurement

BREIMO is the contact-free, optical strip width measuring system for steel strip material in continuously running processes.

Consisting of a measuring frame with two sensor positioning devices (EVK), the corresponding light emitters (LLS) and a common linear stroke transducer, BREIMO is an extremely reliable strip width measuring system. All of the advantages offered by the EVK can also be found in the BREIMO system, such as, for example, a robustness to external malfunctions.

Changes to the strip edge position are continuously detected and taken into account when calculating and displaying the strip width.

EMG iSCAN

Slab Dimension / Position Measurement and Tracking

Width, length and thickness – EMG iSCAN® is your solution for hot strands and slabs. The precise and non-contact slab dimension measurement is performed with a customer-based arrangement of laser-based sensors. Even under great heat, our sensors keep a cool head. Therefore, ideally suited for harsh environmental conditions.

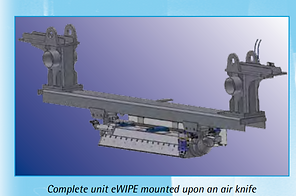

EMG eWIPE

Automatic Air Knife Cleaning

The eWIPE Air Knife Cleaning system is a pneumatically operated cleaning tool for air knifes in galvanizing lines. It allows the removal of firmly bonded zinc deposits inside and outside the nozzle lips.

The system mainly consists of:

-

two cleaning devices each including a pneumatic cylinder for mounting on a stable substructure upon each air knife

-

two connector bars for quick connection of the

pneumatic and electrical lines -

one stand with pneumatic control system

one small electric cabinet for the electronic control

EMG Drive Solution/Brake Thruster

The ELDRO® and ELHY® electrohydraulic thrusters from EMG ensure a safe and "gentle" braking process in combination with modern drum and disk brakes. In addition, they ensure personal safety and the safety of machines.

ELDRO CLASSIC

.png)

ELDRO - DC Series

ELDRO EXPLOSSION-PROOF

ELDRO DYNAMIC

ELHY SERIES - Electrohydraulic Thrusters